Transportation Event Data Recorders

This paper was presented by Dr. McElroy at the World Accident Reconstruction Exposition, WREX 2000

ABSTRACT

Transportation safety has been significantly enhanced because of Event Data Recorders (EDR). National Transportation Safety Board (NTSB) transportation modes are defined as aviation, railway, marine, pipeline, and surface or highway. Highway EDR’s include Original Equipment Manufacturer (OEM) Type I systems offered by General Motors and Ford and the Type II systems offered by VDO Mannesmann and LMS MACBOX. EDR’s provide “black box” collision data. National Highway Traffic Safety Administration (NHTSA) has a special committee which has focused on EDR data and related protocol. Recorded data provides an accurate history of key issues leading up to a collision, helping to eliminate or reduce much of the work involved in collision analysis.

TRANSPORTATION MODES & EDR

AVIATION DATA RECORDERS

Aviation reliability has dropped current airline accidents to a rate of 1/16 what they were in 1960. Significant credit to this improvement in safety can be attributed to the “black box” or crash recorder which today is generically referred to as the Event Data Recorder or EDR. Aviation EDR’s are painted orange however, and are technically referred to as the Cockpit Voice Recorder (CVR) and Flight Data Recorder (FDR). Future aircraft will have two combined EDR’s each with CVR & FDR data. Parallel data recorded on both units will provide higher levels of reliability with one unit mounted in the front of the aircraft and the second unit mounted in the aft section. Because significant aviation EDR information is available to chronicle it’s development, this technology will not be covered to the degree of the other transportation modes which have not been so addressed.

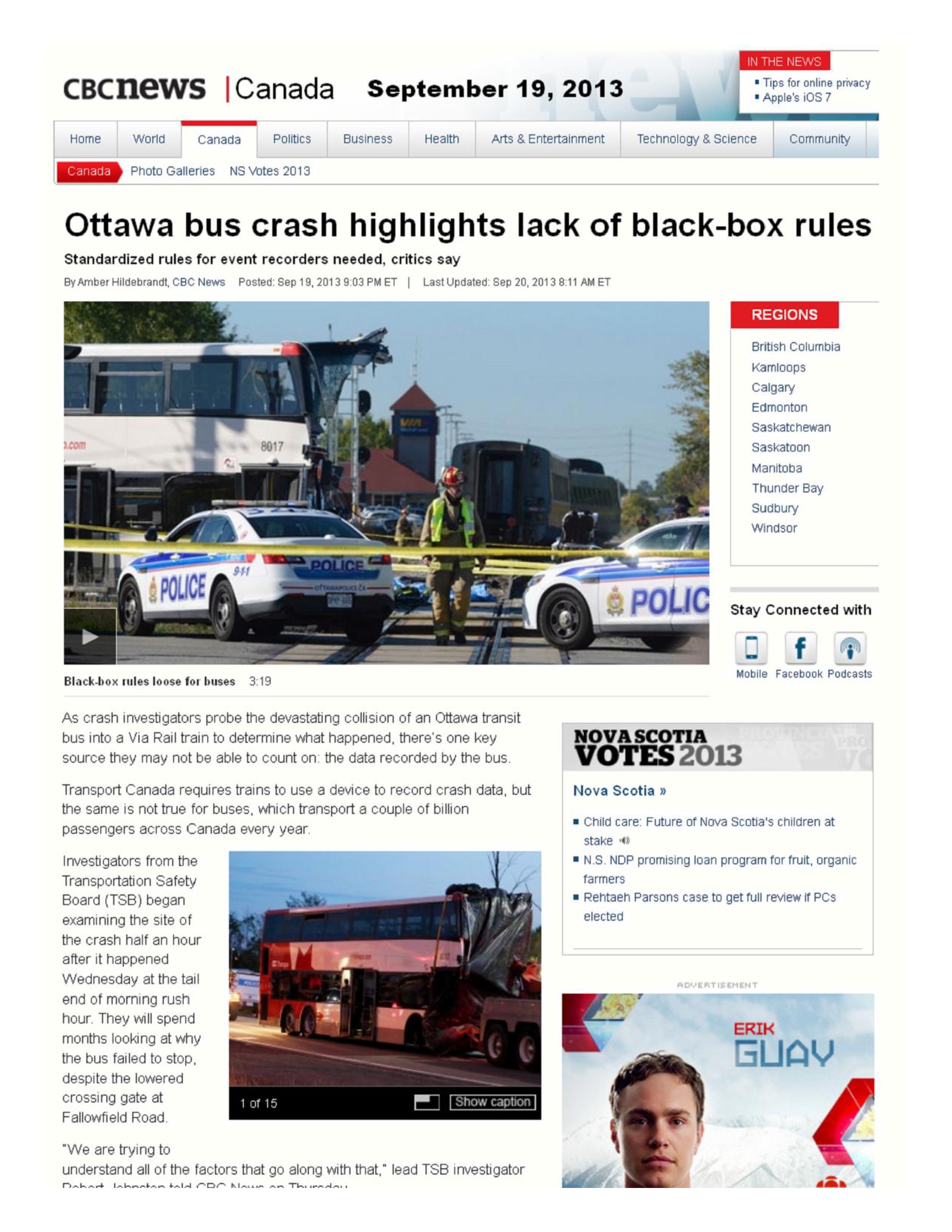

RAIL DATA RECORDERS

In railway accident investigations, the National Transportation Safety Board (NTSB) secures data recovered from various recorders to determine train speed, direction of travel, distance traveled, throttle position, brake application, cab and/or wayside signals, and applicable communications from before and during the accident. Since 1995 the Federal Railroad Administration (FRA) has had regulatory responsibility for establishing minimum parameters to be recorded and established standards that EDR’s must meet. The rail industry also voluntarily records information on train movement and warning devices for its own use.

Initially, railroads, on their own initiative, installed recorders on locomotives as a way to oversee the engineer’s operation of the train and to document the locomotives performance. Since May 1995, the FRA has required an EDR on any train operated faster than 30 miles per hour (49 Code of Federal Regulations [CFR] 229.5 and 229.135). Under this requirement a recorder must, at minimum be tamper resistant and capable of recording the following parameters: train speed, direction of motion, time, distance, throttle position, brake applications and operations, and where equipped, cab signals during the most recent 48-hours of operation.

In addition, the railroad industry has voluntarily developed other uses of recorders. Recorders allow the railroads to verify remote operation of devices that provide for safe train operations as well as for public safety. Recorders monitor highway grade crossings interconnected for pre-emption of traffic signals for time, train speed, and activation of pre-emption circuitry. Selected centralized traffic controlled interlockings use recording systems to document time, and sequential position of relays for signals controlling train movements. Railroad wayside-equipment defect detectors can detect certain defects as a train passes over sensors and scanners at track level which can record and then send relevant functional technical information to the train crew.

Each of these devices can maintain a record of the activity for relevant parameters as prescribed by the railroad. Railroads also voluntarily record radio communications between dispatchers and train crews as well as the communications among railroad-emergency coordinators, emergency and law enforcement agencies, and other organizations during an emergency. Railroads can also monitor the dispatchers’ instructions to train crews for compliance with the railroad’s own rules and with the instructions authorizing train operations. Railroads can also monitor communications with outside agencies for effectiveness, timeliness, and accuracy of information provided during emergencies.

VOYAGE DATA RECORDERS

A ship can sink without anyone being aware of it for several days. Integrating EDR in the compact environment of an aircraft is one thing, fitting it on a merchant vessel is something entirely different, and the costs of so doing can be significant. In a very competitive and loosely structured international marine industry there are many who see little or no commercial advantage to fitting EDR. The safety record of some ship owners and flag states is far from satisfactory. In the past ten years about 1000 merchant ships have been lost and many more have been involved in lesser events to varying degrees.

The human toll has been equally horrifying. Marine transportation, perhaps more than any other industry, is influenced by the realities of the market place with well run, properly manned, modern vessels having to compete with badly maintained, poorly managed, indifferently crewed vessels of excessive age. A modern well run ship representing a greater investment in training and safety is often at a commercial disadvantage when compared with a vessel at the other end of the spectrum where safety matters are barely a consideration and operating costs are considerably less. Accidents can, and do, occur to vessels in any category and sailing under any flag. Leading flag states go to great lengths to establish what happens by fully investigating event circumstances and by making findings available for the benefit of all.

States with independent accident investigation organizations are recognized as being the most effective in view of their impartiality and the trend towards making marine accident reports public. Many nations, despite having large parts of the world’s fleet sailing under their flags, do little to fulfill the international requirement to investigate marine accidents when they do occur. If an investigation is carried out there is, too often, little or no attempt to publish a report and any contribution to improving safety at sea is lost. Marine accident investigation is all about reconstructing marine events. Unlike aviation where access to data recorders can provide answers to complex questions and establish patterns of human behavior, the marine accident investigator typically has to rely much more on physical evidence and the recollections of those involved. Occasions arise when there are no survivors and the process of reconstruction becomes even more difficult. Ships sink, sometimes without a trace. EDR technology will ensure that a true account of what occurred in an accident can be obtained.

The case for fitting EDR’s in ships has been made. In July 1997 the Safety of Navigation Sub-Committee of the International Maritime Organization (IMO) approved draft standards for shipborne Voyage Data Recorders (VDRs) although, crucially, agreement has yet to be reached on which ships must carry the recorders and when. The European Community has acted ahead of the IMO requirements to ensure that all passenger ferries operating in Europe are equipped with VDRs to IMO standards.

PIPELINE DATA RECORDERS

Operating under the jurisdiction of the U. S. Federal Energy Regulatory Commission, interstate pipelines provide open access for transportation of natural gas. Gas enters an interstate pipeline from a geographic gathering system and from interconnecting pipelines. Beginning at individual wellheads, a gathering system usually consist of smaller diameter pipe operating at lower pressure. Gas conditioning is usually performed to reduce contaminants such as water from gathered gas before it is compressed into the transmission system. Gas leaves the transmission system through delivery points to other interstate pipelines, local distribution companies and directly to end users such as industrial facilities and power plants. Local distribution systems deliver gas to residential, commercial and industrial consumers.

Basic components of an interstate pipeline include steel pipe, valves, compression, processing and storage facilities. Pipe sizes vary widely with much of the pipe in the 20-inch to 36-inch diameter range and wall thickness of about one-quarter to one-half inch. A typical range of operating pressures for a transmission system is 300 to 1440 psig. Powered by natural gas or electricity, compression is one of two types: reciprocating or centrifugal. Processing facilities extract undesirable contaminants (such as hydrogen sulfide and water) and marketable hydrocarbons (such as propane and gasoline). Storage facilities have been developed from depleted oil fields, coal mines, salt domes, aquifers and reefs. These facilities can be used for peak-shaving hourly demands and short-term, as well as, seasonal storage of gas. Much of the gas that is transported on interstate pipelines is nominated, that is, scheduled in advance of actual gas flow. Deliveries into local distribution companies that serve weather-sensitive markets, however, cannot be known with absolute certainty. Such demand is met in part with “no-notice” service, which is usually supplied from inventories of the customers’ gas, which is stored in the pipeline’s storage facilities. Recorders monitor production, transmission, compression, switching, valve operation and storage. Remote devices are radio transmitted to a central facility.

HIGHWAY EVENT DATA RECORDERS

EDR FOUNDATION

In 1997, 42,000 people were killed in highway accidents in the United States. The exact cause of an accident is often unknown and, therefore, conclusions relating to the safety afforded by the vehicle to the occupant cannot be made. In addition, safety hazards in the highway environment are often not discovered due to the lack of information. Accident reconstruction is a tool commonly used by the National Transportation Safety Board (NTSB) to investigate the accident sequence, but data are often lacking and accurate reconstructions are difficult and time-consuming. Because many assumptions are made in this process, the reconstruction is not exact, making it difficult to accurately predict occupant kinematics and to identify potential safety hazards within the vehicles. Vehicle recorders would eliminate much of the guesswork involved in reconstructing accidents, enabling a more accurate assessment of occupant injuries, driver performance, and safety hazards within and around a vehicle.

DRIVER & VEHICLE DATA

TACHOGRAPH

The tachograph is a device that graphically records the time and engine speed. The name tachograph comes from the graphical recording of the tachometer or engine speed. In all vehicles, there is a direct correlation from the engine speed to the vehicle speed given the different gear ratios of the transmission, the gear ratios of the axle and the wheel size as measured in revolutions per mile. Argo and Mannesmann VDO are two long time manufacturers of this type of equipment. Many units are built so that they install in the dash directly in front of the driver, next to the vehicle speedometer. An alternate installation is in the dash in front of the passenger. The recordings are done on graph paper, most often installed from the front of the unit. An ink pen records the engine speed on circular graph paper that is automatically advanced according to the internal clock of the tachograph. Graph paper is removed on a regular basis and maintained by the fleet for government records.

Electronic Tachogragh / Fleet Management Systems

Much information concerning the accident vehicles is needed to reconstruct an accident accurately. This information includes both driver inputs and vehicle outputs. The driver inputs would include steering angles; application of brakes and throttle; gear selection; engine braking; and use of lights, turn signals, cruise control, wipers, and horn at various increments prior to and during the accident sequence. Information is also necessary on driver restraint use and occupant seating location. The vehicle output parameters that are needed include the pre-impact speed, engine rpm and gear selection, acceleration history, braking efficiency, the use of cruise control and anti-lock braking systems, and activation of passive restraints.

Typically in highway accidents, the driver inputs and the vehicle outputs are derived from witness statements, or physical evidence such as the impact location, tire marks, and the final resting position of the vehicles. Unfortunately, witness statements are often in conflict, biased, and perhaps based on past experience, adding confusion to variables such as initial speed or speed at impact. Further, the accident typically occurs within 0.10 seconds, a speed at which witnesses cannot always accurately comprehend vehicle interactions. Furthermore, physical evidence can be limited if road conditions are not ideal or if evidence is not collected immediately after the accident.

Human Performance: Recorded information could help investigators determine the drivers’ actions before and during the accident. These inputs will help to refine the vehicle and occupant dynamics during the accident. The recorded information may also help to assess if the driver was fatigued, impaired, or not making evasive maneuvers. For example, a lack of steering reversals may indicate fatigue. Such information will help to assess countermeasures for preventing accidents.

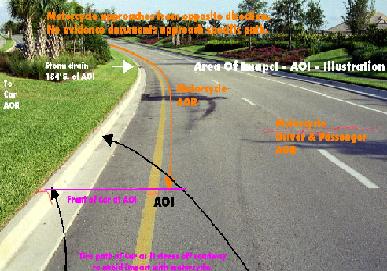

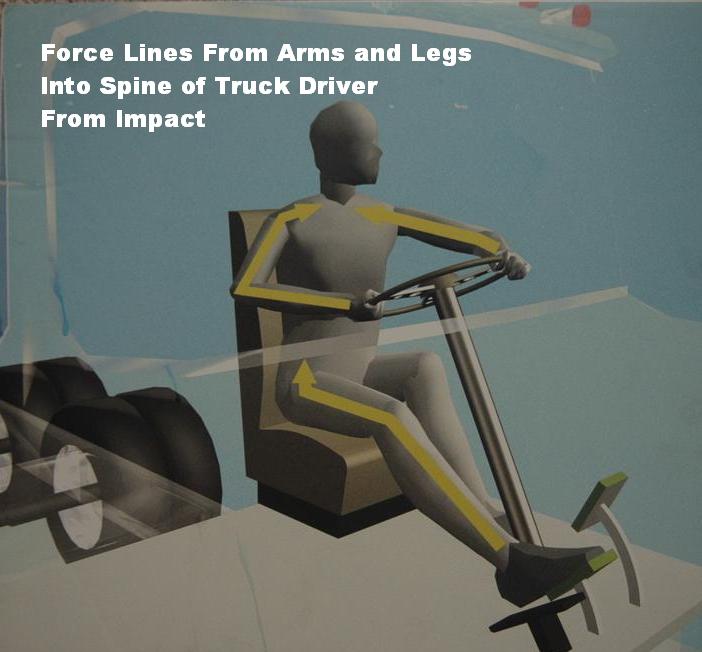

Biomechanics: Once accurate information on vehicle performance and driver response is known, the reconstruction may then be used to assess occupant kinematics (Figure 2) and occupant protection within the vehicle. The more accurate the vehicle dynamics, the more accurate the occupant simulation. Better occupant simulation will result in more effective design changes that improve occupant safety.

NTSB IDENTIFIES NEED FOR EDR

In 1997, the National Transportation Safety Board (NTSB) made three particular recommendations that are helping to build an “Automatic Lifesaving System for a Safer America”. The NTSB is to be commended for its recommendations on crash recorders (H-97-18 and H-97-21), for holding this Symposium, and for its recommendation (H-96-13) to increase funding for motor vehicle safety efforts at the State level.

To the National Highway Traffic Safety Administration (NHTSA):

· H-97-18 “Develop and implement, in conjunction with the domestic and international automobile manufacturers, a plan to gather better information on crash pulses and other crash parameters in actual crashes, utilizing current or augmented crash sensing and recording devices.”

To the Domestic and International Automobile Manufacturers:

· H-97-21 “Develop and implement, in conjunction with the National Highway Traffic Safety Administration, a plan to gather better information on crash pulses and other crash parameters in actual crashes, utilizing current or augmented crash sensing and recording devices.”

Crash recorder data could be used in a national program for continuous improvements in the prevention and treatment of crash injuries. The systematic capture and organization of crash recorder data will enable citizens, governments (at all levels) and the auto, insurance, and health care industries to contribute to the building of a safer America on a solid scientific foundation of objective data. The technological availability of crash recorder data now provides the nation with the opportunity to improve upon the triage guidelines currently in use worldwide based upon work done a decade ago [25]. For one example of additional benefits with systematized crash recorder data, state highway departments could obtain a wealth of information, including location, on all serious injury crashes for continuous system improvements.

MVSRAC

In 1998, NHTSA requested that its Motor Vehicle Safety Research Advisory Committee (MVSRAC) approve a working group for Event Data Recorders under its Crashworthiness Subcommittee. The Working Group consists of representatives from the motor vehicle industry, academia, and federal and state governments. NHTSA’s MVSRAC Working Group meetings are closed to the public. Their mission is to collect facts and report them to the parent Subcommittee. The Subcommittee and full committee meetings are open to the public. The Working Group invites experts to assist in the fact finding mission and maintains the public file discussed below:

The technical objectives of the Working Group include: 1) defining functional and performance requirements for event data recorders, 2) understanding present technology, 3) developing a set of data definitions, 4) discussing various uses for the data, 5) considering related legal & privacy issues, and 6) standardization of publicly usable data.

The Working Group meetings were held in Washington, D.C. The meetings were attended by about 25 working group members and other NHTSA and FHWA interested parties. During these meetings, manufacturers have presented information on the current status of event recording technology at their respective companies. Government and other interested safety researchers have presented their needs for event data. The Working Group has started an effort to list the most desired data for inclusion in on-board recorders and is currently discussing privacy concerns, data ownership, and other policy and legal issues.

It is anticipated that the Working Group will continue its activities until the objectives are met. The group plans on writing a report which will include the fact finding results of the group, which should be completed by late 2000. The Working Group places its public material in the DOT Docket system. This information will be available by mid-1999 from the Docket Management System. Access can be gained on the Internet at: http://dms.dot.gov/ – click on “Search” about half-way down the page – click on “Docket Search Form” – fill in the docket ID with “5218” – select “NHTSA” for the agency – and “2000” for the calendar year and press search.

NHTSA EDR COMMITTEE

A Task Force was formed through the sponsorship of NHTSA and met on October 2, 1998 to address research requirements for on-vehicle event data recorders. Participants included representatives from NHTSA, FHWA, NTSB, TRB, the major American automobile, truck, and bus manufacturers, and several other vehicle manufacturers. The Task Force members recognized issues regarding liability and privacy. The objective offered by NHTSA for the task Force was to facilitate the collection and utilization of collision avoidance and crash worthiness data from on-vehicle event data recorders (EDR). The scope was limited to research rather than regulatory initiatives. Current EDR systems are considered to be early generation systems with enormous potential for collecting and using pre-crash, crash, and post-crash data. EDR’s are defined as devices capable of gathering, storing and displaying data elements from a vehicle in motion as pre-crash, crash and post-crash.

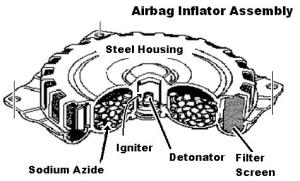

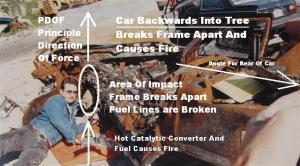

Event data elements include but are not limited to active suspension measurements, advanced systems, air bag inflation time, air bag status, airbag on/off switch position, automatic collision notification, battery voltage, belt status of each passenger, brake status-service, brake status-ABS, collision avoidance, braking, steering, etc., crash pulse-longitudinal, crash-pulse lateral, CSS presence indicator, Delta-V-longitudinal, Delta-V-lateral, electronic compass heading, engine throttle status, engine RPM, environment as ice, wet, temperature, lamination & other, fuel level, lamp status, location via GPS data, number of occupants, principle direction of force, PRNDL position, roll angle, seat position, stability control, steering wheel angle, steering wheel tilt position, steering wheel rate, time and date, traction control, traction coefficient estimated from ABS computer, transmission selection, turn signal operation, vehicle mileage, vehicle speed, VIN, wheel speeds, windshield wiper status, yaw rate, turn-key start time, vehicle movement time, location at start, velocity at crash, trip time at collision or crash, fire in cabin, water in cabin, audio-clip at air bag deployment, etc.

GM OEM EDR

The National Transportation Safety Board has recommended that automobile manufacturers and the National Highway Traffic Safety Administration work cooperatively to gather information on automotive crashes using on-board collision sensing and recording devices. Since 1974, General Motors’ (GM) airbag equipped production vehicles have recorded airbag status and crash severity data for impacts that caused a deployment. Many of these systems also recorded data during “near-deployment” events, i.e., impacts that are not severe enough to deploy the airbag(s). GM design engineers have used this information to improve the performance of airbag sensing systems and NHTSA researchers have used it to help understand the field performance of alternative airbag system designs. Beginning with the 1999 model year, the capability to record pre-crash vehicle speed, engine RPM, throttle position, and brake switch on/off status has been added to some GM vehicles. This paper discusses the evolution and contents of the current GM event data recording capability, how other researchers working to develop a safer highway transportation system might acquire and utilize the information, and the status of the NHTSA Motor Vehicle Safety Research Advisory Committee’s Event Data Recorder Working Group effort to develop a uniform approach to recording such data.

Evolution of GM Event Data Recording

GM introduced the first regular production driver/passenger airbag systems as an option in selected 1974 production vehicles. They incorporated electromechanical g-level sensors, a diagnostic circuit that continually monitored the readiness of the airbag control circuits, and an instrument panel Readiness and Warning lamp that illuminated if a malfunction was detected. The data recording feature utilized fuses to indicate when a deployment command was given and stored the approximate time the vehicle had been operated with the warning lamp illuminated. In 1990, a more complex Diagnostic and Energy Reserve Module (DERM) was introduced with the added capability to record closure times for both the arming and discriminating sensors as well as any fault codes present at the time of deployment. In 1992, GM installed sophisticated crash-data recorders on 70 Indy race cars. While impractical for high volume production, these recorders provided new information on human body tolerance to impact that can help improve both passenger vehicle occupant and race car driver safety. As an example, the data demonstrated that well restrained healthy, male race car drivers survive impacts involving a velocity change of more than 60 mph and producing more than 100 g’s of vehicle deceleration. Such information will be helpful to biomechanics experts refining their understanding of human injury potential.

Changes in race car design have also been made using data obtained from the on-board recording capability. Specifically, it was observed that a substantial deceleration pulse occurred when the vehicle’s differential “bottomed out” during rear impact crashes. Knowing this, a simple, light weight impact attenuator was designed that, in combination with improved head padding, is believed to have substantially reduced the number of serious driver injuries during the 1998 racing season.

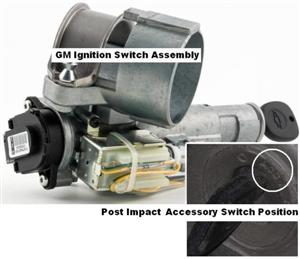

For the 1994 model year, the multiple electromechanical switches previously used for crash sensing were replaced by the combination of a single solid state analog accelerometer and a computer algorithm integrated in a Sensing & Diagnostic Module (SDM). The SDM also computed and stored the change in longitudinal vehicle velocity (DV) during the impact to provide an estimate of crash severity. This feature allowed GM engineers to obtain restraint system performance data when a vehicle was involved in a deployment event or experienced an impact related change in longitudinal velocity but did not command deployment (i.e. a near-deployment event). The SDM also added the capability to record the status of the driver’s belt switch (buckled or unbuckled) for deployment and near-deployment events. Certain 1999 model year GM vehicles have the added capability to record vehicle systems status data for a few seconds prior to an impact. Vehicle speed, engine RPM, throttle position, and brake switch on/off status are recorded for the five seconds preceding a deployment or near-deployment event. Almost all GM vehicles will add that capability over the next few years.

To make EDR data available to all interested researchers, GM has selected Vetronix Corporation of Santa Barbara, California to develop software and interface cables allowing the data to be downloaded to commonly used laptop computers (see Figure 6). Data useful to such researchers (DV, belt use, pre-impact data, etc.) will be stored and displayed in a standard format using engineering units while data requiring expert knowledge to interpret will continue to be stored in hexadecimal format. The new tool will also allow the user to input other pertinent information (e.g., investigator’s name) and export the data to a remote database. Like the current EDRU, interface cables will be provided for vehicles that cannot be powered up after a crash. These kits are expected to be commercially available during the summer of 1999 with the initial units going to GM and NHTSA crash investigators.

SUMMARY

Accident reconstruction/simulation is a difficult and time-consuming process. Event recorders not only simplify the reconstruction process, but they also increase the accuracy of the reconstruction resulting in more detailed conclusions concerning safety.

This accident reconstruction diagram was prepared using data from an emergency vehicle tachograph recording device.